We are specialized in manufacturing all types of Ferrous & Non Ferrous Investment Casting, Lost Wax Castings, Feinguss, Micro Fusion and more according to customers’ requirements. Also, we can offer fully finished and ready-to-use machined components. We are a focused 'leading edge' engineering group providing cost-effective solutions to technically highly complex and demanding applications in every area of our expertise.

Our product range includes casting of firefighting equipment, automobile parts, hydraulic cylinder parts, pumps and valves, engineering machinery parts, mining machinery parts, agricultural machinery parts, oil and gas industry parts, marine, electrical parts, textile machinery parts, machinery tool parts, material handling system parts and more.

| Total Plant Area | 65000 sq. feet |

| Plant capacity | 800 Tons / Annum |

| Spare capacity | 500 Tons / Annum |

| Materials We Use | All carbon steel grades, All stainless steel grades, All duplex steel grades, All Copper grades & Copper alloy etc… |

| Product Range | 50 grams to 150 Kg Single Piece |

Investment Casting Process

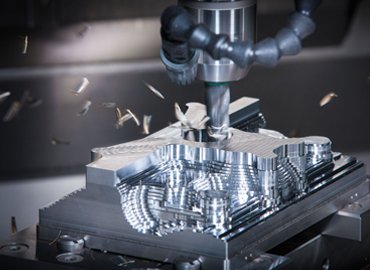

Step 1. Tooling Making

To achieve precision products, making tooling is the first step to start investment castings. Such tooling or pattern will be precision machined by CNC center.

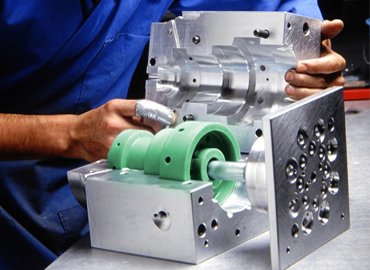

Step 2. Wax Injection and Pattern Assembly

After a pair of casting patterns is completed, we will first make wax pattern, such wax pattern is obtained by injecting wax into the pattern. And you will see a model with the same dimensions of desired products. Again, we will repeat the injection job for more wax patterns. Then assemble these wax patterns onto the sprue. Finally hang these pattern assemblies in the room temperature for drying.

Step 3. Shell Building

In this step, the pattern assembly will be dipped into ceramic slurry, and coated with a refractory material. This process needs to be repeated several times until reaching a certain thickness and strength. Thus, the ceramic shell is built and then dried in an atmospherically-controlled environment.

Step 4. De waxing

Placing the shell in a steam autoclave and rapidly heated, so that the wax will be melt and run out through the gate and pouring up under high temperature. The ceramic shell molds must be fired to burn out the last traces of pattern material and to preheat the mold in preparation for casting, usually in the range of 1,600-2,000 degrees Fahrenheit. So investment casting also named as “lost wax casting”.

Step 5. Casting

Casting is the key step in the whole investment casting process. After dewax, we will first melt the steel ingots into liquid status, and pour the liquid metal into the sprue, then cool it under room temperature for a while.

Step 6. Knock out

Break the ceramic shell, and cut the individual investment castings from the sprue. Finally remove the excess metal from casting body by grinding.

Step 7. Heat Treatment

To improve the mechanical properties of casting blanks, heat treatment is usually done after finishing castings. Main heat treatment processes are: Normalizing, tempering, annealing, hardening and tempering.

Step 8. Shot Blasting/Sand Blasting

To remove scales and achieve better surface finish, investment castings will be shot blasted or sand blasted by small steel balls.

Step 9. Inspection

Inspection is also a necessary step for quality investment castings. Our engineer will do dimensional inspection, 100% surface inspection, inner defects inspection and other inspection jobs according to requirements of products.

Step 10. Package & Delivery

For Domestic supply we pack investment casting parts according to customer’s packing requirement and ship though reputed local carrier.

For export orders of investment casting parts, to protect products from damage, we pack products with ploy bag, and then put into standard wooden case. Besides, we can also customize package according to customer’s requirements. Located near Mundra and JNPT port, it is quite convenient for us to deliver products to clients’ destination ports both by sea or air.

© 2025 Pinnacle Industries. All Rights Reserved.