At Pinnacle we are specialized in closed die hot forging. We supply forging components to automobile, transmission, hydraulic, mining equipment, marine, agriculture machinery, and power generation manufacturers.

We are one stop solution for any kind of forging need from small scale to large scale production with fully machining capability.

We are leader in producing high quality and close tolerance forging parts as per customer need.

We are having 1.5 MT and 3 MT forging hammer with in-house tool making, heat treatment, shot blasting, machining and inspection facility.

| Total Land Area | 24000 sq. feet |

| Total Plant Area | 12000 sq. feet |

| Plant Installed Capacity | 5000 MT / Annum |

| Plant Spare Capacity | 2000 MT / Annum |

| Materials We Use | All grades of Carbon Steel, Alloy steel, Super Alloys and Special Alloys etc… |

| Product Range | 100 grams to 30 Kg single piece |

Forging Process

Step 1. Die design & making

Die making is the first step for close die forging parts. Once a new order is placed, our engineer will design die according to forging drawing received from customers. A set of forging die will include forging die, trimming die and flatten die. We have in house forging die manufacturing facility. Our technical team ensures accurate calculation of the volume of metal billet that fits into the die to avoid under filling and overfilling of the dies.

Step 2. Billet cutting & heating

In our forging company, we keep stock of common steel material specifications for continuous production. After die development is completed, steel billets will be taken from our material warehouse, then cut into required length and heated by medium frequency induction furnace before forging.

Step 3. Closed Die Forging

After heating billets, heated steel bars will be placed under upper and lower dies, and then pressed into desire shape, but redundant material will shown around the product, which is named as flash.

Step 4. Trimming

Now forging blanks with flash are obtained, to remove the flash, the forged steel blanks will be put under trimming dies and pressed again. In this step, a whole forging blank is finished.

Step 5. Heat Treatment

To improve the strength and mechanical properties, heat treatment will be done after forging. Common heat treatment methods for steel forgings are normalizing, quenching, annealing, tempering & hardening. Of course, heat treatment is only operated when it is required.

Step 6. Shot Blasting

To remove the scale and achieve better surface finish, steel forgings will be shot blasted. After shot blasting process, products will look much more clear and smooth.

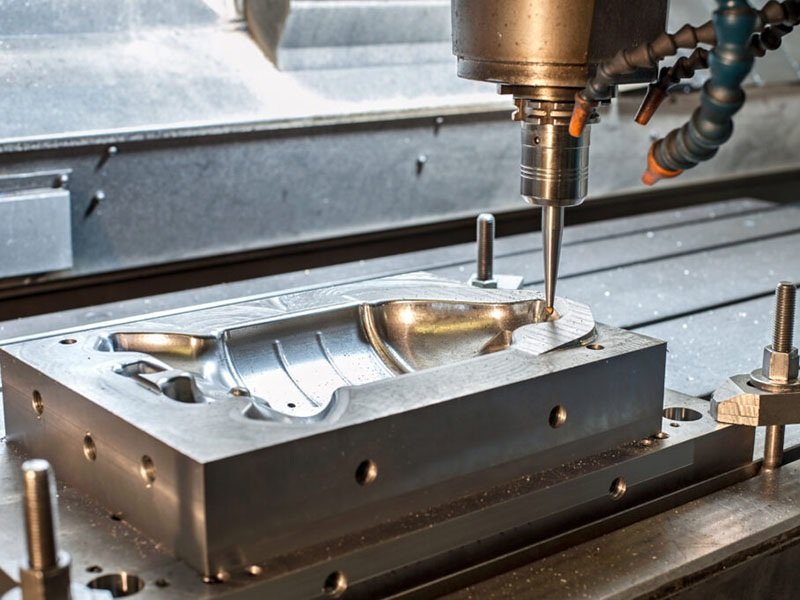

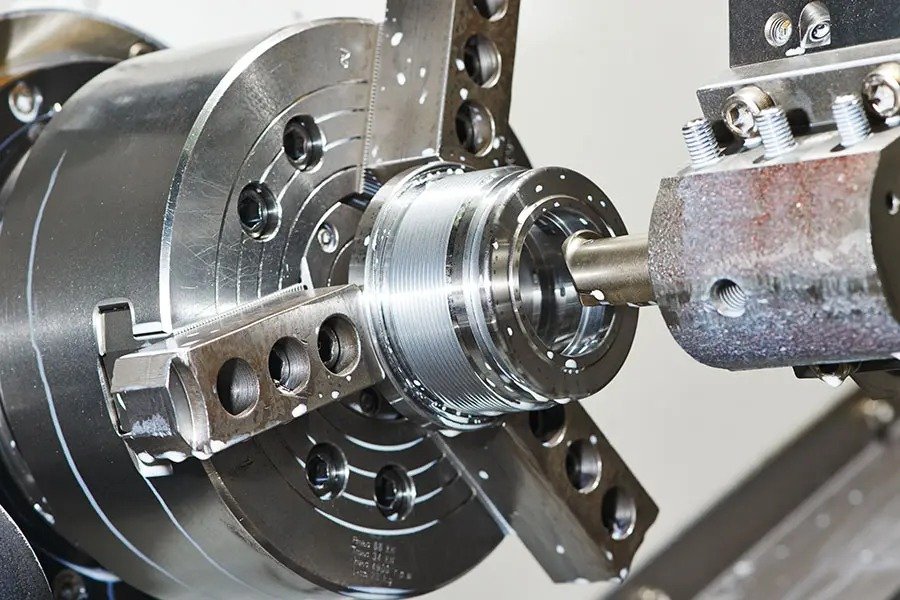

Step 7. Machining

If any forging part requires CNC machining to be carried out then we have in house machining capability to fulfill machining requirement. You can check list of CNC turning, milling, VMC, HMC, VTL machineries list available with us under CNC MACHINING page of our website.

Step 8. Inspection

Inspection of any part is a very important step before dispatch from our premises. We carry out in process inspection of each part and final inspection of a sample lot to trace any part or dimension running out of tolerance.

Here is the lists of our state-of-the art measuring equipment are highly efficient to measure these parts:

Roughness tester by Mahr

High precision calipers, micrometers by Mitutoyo

Plug, Slip, Snap, bore dial, and digital gauges.

Step 9. Surface Treatment

If there is no special surface treatment requirement then anti-rust oil is enough before package. Sometimes special surface treatments are also required according to the application of steel forgings, like color painting, zinc plating, electro plating, etc.

Step 10. Package & delivery

For Domestic supply we pack forging parts according to customer’s packing requirement and ship though reputed local carrier.

For export orders of forging parts, to protect products from damage, we pack products with ploy bag, and then put into standard wooden case. Besides, we can also customize package according to customer’s requirements. Located near Mundra and JNPT port, it is quite convenient for us to deliver products to clients’ destination ports both by sea or air.

© 2025 Pinnacle Industries. All Rights Reserved.